PVD - Prefabricated Vertical Drains

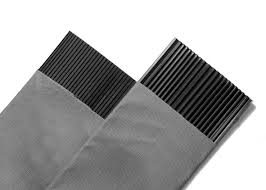

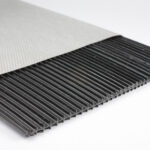

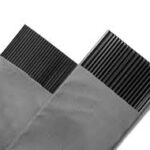

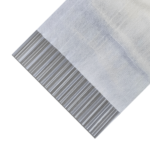

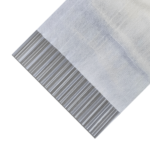

Prefabricated Vertical Drains (PVDs), also known as Wick Drains, are made up of a strong plastic core usually, polypropylene wrapped around a synthetic geotextile to help water flow through slow-draining soils. It reduces soil particle ingress and clogging. Prefabricated vertical drains have a high flow capacity and are frequently used in conjunction with surcharging to speed up preconstruction soil compaction. They’re inserted in soft clay layers to allow for faster consolidation and increased shear strength.

The pore water pressure is increased more quickly when penetrating soft clays, which reduces preloading time, increases water dissipation, shortens pore water travel distance, and compresses soil voids. The pressure in the pore water might have an impact on the drain flow. Pore water will flow horizontally to the nearest drain instead of vertically to an overlaying or underlying drainage layer in this situation.

These serve as drainage channels for pore water in soft compressible soils that consolidate more quickly when subjected to a steady surcharge load. There are multiple other uses for PVDs. They could be used to lessen pile-downdown drag or improve storage capacity for future landfills and trash disposal sites. PVD is being used to collect and extract contaminated groundwater, which can be combined with cutoff walls to assure complete withdrawal.

Advantages of Prefabricated Vertical Drains

All installation parameters are recorded by automated data acquisition.

Drainage and in turn construction schedules are accelerated.

Aids in consolidation of tailing ponds and leach pads.

Installation is done in high speed.

Market Uses Of Prefabricated Vertical Drains (PVD)

Infrastructure

The drains are for example used for the construction of embankments for roads, railways, the preloading of runways, and aprons for airports, and infilling of port areas

Dredging & Land Reclamation

Drains are used when reclamations are constructed on soft deposits

Mining

Drains are used in Tailing ponds to accelerate consolidation or to increase the leaching effect in using embankments

Construction

Drains are used to make green and brownfield areas suitable for the construction of for example houses, warehouses, and tank farms by reducing the residual settlement of the terrain

Flood Protection

Drains are used in the flood protection market to increase the stability of dikes and embankments during widening projects.

Previous

Next

FAQ's

Prefabricated Vertical Drains, also called Wick Drains or band drains, are geotextile-wrapped plastic strips with molded channels that are prefabricated. These serve as drainage channels for pore water in soft compressible soils that consolidate more quickly when subjected to a steady surcharge load.

The major applications of PVDs are below:

– Construction of roads, airports, ports, railways, and embankments.

– Used in Industrial projects

– Used in Land reclamation projects.

– Silty soil and marine sediment drainage.

– Construction of roads, airports, ports, railways, and embankments.

– Used in Industrial projects

– Used in Land reclamation projects.

– Silty soil and marine sediment drainage.

The following steps are involved in installing the prefabricated vertical drains:

1) A hollow steel mandrel surrounding the PVD material is used to install prefabricated vertical drains. The first step is to use a stitcher to drive the mandrel into the ground.

2) Install the PVD roll on the side of the leader and channel and mount it through the steel mandrel.

3) At the bottom layer of the mandrel, the PVD is looped through a steel anchor plate. The anchor plate will be firmly held and retained at the desired depth by installing it at a consistent speed into the compressible soft soil. The mandrel is retrieved from the ground once the desired depth has been reached.

4) The mandrel is retrieved from the ground and the PVD is cut off.

5) All the above steps should be repeated during the entire installation process.

1) A hollow steel mandrel surrounding the PVD material is used to install prefabricated vertical drains. The first step is to use a stitcher to drive the mandrel into the ground.

2) Install the PVD roll on the side of the leader and channel and mount it through the steel mandrel.

3) At the bottom layer of the mandrel, the PVD is looped through a steel anchor plate. The anchor plate will be firmly held and retained at the desired depth by installing it at a consistent speed into the compressible soft soil. The mandrel is retrieved from the ground once the desired depth has been reached.

4) The mandrel is retrieved from the ground and the PVD is cut off.

5) All the above steps should be repeated during the entire installation process.

– Consolidate foundation soils more quickly.

– During settlement, provides a path for entrained water.

– Less expensive than sand drainage or staged construction.

– Trained Layfield crews are used for installation.

– During settlement, provides a path for entrained water.

– Less expensive than sand drainage or staged construction.

– Trained Layfield crews are used for installation.