Geotextile Fabric for Waterproofing

We bring to our clients a wholesome and sturdy range of Geotextile that is stitch-less and is available in various colors and lengths to suit the requirement of the clients. These are used in controlling landslides and soil erosion and are usually laid along the river embankments, sides, canal banks, and hill slopes. These are a range of woven open mesh fabrics made from 100% natural and biodegradable coir. These natural nettings hold the soil and seed intact during the establishment of vegetative cover. When it biodegrades it adds organic nutrients to the soil. Coir Geotextiles are “eco-friendly” products.

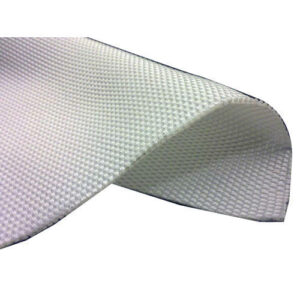

Non-Woven Geotextiles:

We take pride in manufacturing fabrics that build the infrastructure of nations and make them stronger and long-lasting. The following functional properties of Geotextiles make them well-suited for a wide range of applications.

Separation: Geotextile is permeable to water but prevents the mixing of aggregate and soil when laid as a separator between the subsoil and aggregates. It also enhances the strength, durability, and structural integrity of the structure.

Reinforcement: The high tensile strength of Geotextiles, combined with their property of elongation, makes them the best material to increase the load-bearing capacity of weak soils. Hence most ideal to be used in road construction, slope protection, etc.

Filtration: Minute perforations in the Geotextiles are designed to facilitate water flow & restricting the minute soil particles. As a result, the water pressure is reduced and the load-bearing capacity of the structure is enhanced.

Protection: Geotextiles, due to high puncture resistance, prevent the pumping of aggregates into the soil. This results in a stable soil structure.

Stress Reduction: Non-woven Geotextiles are designed to restrict the movement of different road layers and prevent reflective cracking. These attributes together with separation, filtration, protection, and reinforcement functions make Geotextiles, a preferred choice for road construction and repair.

Woven Geotextiles:

Woven Geotextiles are the strongest fabrics available for erosion control, stabilization, and aggregate separation. They are characterized by high tensile strengths at low elongation, hence yielding high tensile modulus. These woven geotextiles are dimensionally stable, resistant to Ultra Violet (UV) degradation engineered to be mechanically and chemically stable in aggressive soil environments, and are also resistant to biological environments normally found in soil.

Woven Geotextile is produced of 100% high-tenacity, high molecular weight multifilament polyester (PET) yarns. They deliver the higher ultimate tensile strength properties, resistance to installation damage, and exceptional creep resistance is woven Geotextile has excellent chemical and biological resistance and assured durability for long-term applications.

The inherent characteristics of polyester – high tensile strength and modulus, low elongation, low creep, and high long-term design strength – make these products ideal for soil reinforcement applications. Woven Geotextiles, makes ideal for reinforcement, separation, and stabilization. It is cost-effective and easy to construct.

Advantages of Geotextiles

With the use of a geotextile separator, there is no need for sacrificial aggregate.

Reduction in aggregate crust thickness.

Reduction in depth of excavation.

Woven geotextiles also offer substantial long-term benefits in the form of better performance, longer life, and lower maintenance cost.

Applications of Geotextiles

Separator cum reinforcement for paved/unpaved roads

Basal reinforcement of embankments on soft ground

Subgrade soil stabilization

Reinforced soil on steep slopes

Filters for hard armor erosion control systems

Can be used to construct reinforced soil retaining wall

Stable embankment for safe, rapid, & economic construction.

Previous

Next

FAQ's

Geotextiles refer to permeable synthetic textile materials. Usually, geotextiles are produced from polyester or polypropylene polymers. They are used in increasing soil stability, providing erosion control, and aiding in drainage.

Geotextiles are used in both large and small scale civil engineering projects and serve the below 5 main functions.

1. Separation

2. Reinforcement

3. Filtration

4. Protection

5. Drainage

1. Separation

2. Reinforcement

3. Filtration

4. Protection

5. Drainage

There are 4 different types of Geotextiles and each type has different functions.

1. Woven Geotextiles – They perform the functions of separation and reinforcement.

2. Non-woven Geotextiles – Their main functions are separation, filtration, and drainage.

3. Polyspun Geotextiles – They are non-woven fabrics and their main function is separation.

4. Spunbond Geotextiles – They will provide drainage but not reinforcement.

1. Woven Geotextiles – They perform the functions of separation and reinforcement.

2. Non-woven Geotextiles – Their main functions are separation, filtration, and drainage.

3. Polyspun Geotextiles – They are non-woven fabrics and their main function is separation.

4. Spunbond Geotextiles – They will provide drainage but not reinforcement.

1) The installation area is prepared by removing trees, rocks, stumps, bushes, or any other blockage from the top layer of soil and plants from the subgrade materials. If the soil is weak it must be replaced with granular fill. On the hillsides, trenching is recommended at the top of the slopes.

2) The ground in the project area must be leveled and graded.

3) The geotextile has to be placed in the area that has been prepared for installation. The geotextile fabric has to be flat and tight.

4) The edges of adjustment roles must be overlapped.

5) The fabric must be secured with staples, pins, soil, or other suitable materials.

6) The fills must be placed directly on the geotextiles loosely.

2) The ground in the project area must be leveled and graded.

3) The geotextile has to be placed in the area that has been prepared for installation. The geotextile fabric has to be flat and tight.

4) The edges of adjustment roles must be overlapped.

5) The fabric must be secured with staples, pins, soil, or other suitable materials.

6) The fills must be placed directly on the geotextiles loosely.