HDPE GEOMEMBRANE LINER

High-Density Polyethylene Geomembrane Liners

We offer a wide range of liner HDPE geomembrane that is manufactured using quality raw material. These liner geomembranes are suitable for all types of liquid containment solutions ranging from water pollutants, Road construction, highways, and highway embankments.

High-Density Polyethylene (HDPE) geomembrane liners are used in a wide range of applications. They are durable, cost-effective and one of the most preferred products for lining projects which require low permeability, chemical, ultraviolet resistance, and aging resistance from the intense stresses of weather.

The popularity of High-Density Polyethylene (HDPE) is primarily due to its low initial material cost and excellent chemical resistance. This allows thicker sections to be used compared to other geomembrane materials. A thick, durable, HDPE liner can be placed in exposed applications where the cost of other materials may be prohibitive. HDPE has excellent chemical resistance, which is often the driving force behind its selection. HDPE is a field assembled lining material that cannot be practically fabricated in the shop. All HDPE projects, regardless of size, must be installed by trained installers. HDPE is a versatile material that is used widely across all applications. One of the primary uses of HDPE is to line the base of landfills, where its chemical resistance is put to use. HDPE can also be used in a multitude of secondary containments, pond linings, and water containment projects. HDPE is best used as an exposed lining material and has the UV resistance required for many years of outstanding service.

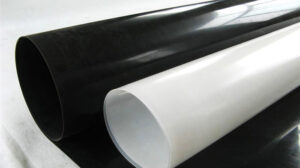

HDPE geomembranes surfaces are made of smooth and textured surfaces. They come in combinations of smooth/smooth, smooth/textured, and textured/textured surfaces. The surface for use is vastly dependent on the application and the requirement. Textured finishes provide higher friction angles to prevent slippage of adjacent materials when lining steep slopes. This product is used in applications that require increased frictional resistance, excellent chemical resistance, and endurance properties.

They are widely used in Tank Liners, Aquaculture, Mining, Water and Solid Waste Management, Fluid Conveyance and Containment, Ash Ponds, Soil Protection and Stabilization, and Land Fill Closures, Ponds and Reservoirs, Irrigation Canals, Waste Containment, and other applications.

Features of HDPE Geomembrane

Resistance to Ultraviolet Rays (UV)

High tensile strength

Longer service life standards

Supplied in wide rolls

Good chemical resistance

White surface available by special order

Conductive layer available by special order

Applications of HDPE Geomembrane

Excellent long term exposed lining material

Landfill liners

Heap leach and mine ponds

All water containment applications

FAQ's

Geomembranes also called as High-Density Polyethylene Liners or HDPE Liners are thin, flexible materials produced in a controlled atmosphere in factories. Geomembranes are permeable and impermeable. In hydropower constructions, impermeable geomembranes are commonly employed as a water barrier, whereas permeable geomembranes are utilized to allow seepage water to pass through without removing the soil. A geomembrane and a geotextile are referred to as a “Geocomposites”.

– Geomembranes are used as liners for various waste conveyance canals.

– They are used as liners in the agriculture industry.

– They are used as waterproofing liners in the tunnels and pipelines.

– Used beneath the highways to prevent pollution from the deicing salts.

– They are also used in containing and transporting potable water and other liquids in the ocean.

– They are used as liners in the agriculture industry.

– They are used as waterproofing liners in the tunnels and pipelines.

– Used beneath the highways to prevent pollution from the deicing salts.

– They are also used in containing and transporting potable water and other liquids in the ocean.

– Helps in sustaining the water quality.

– Helps in soil erosion control.

– Low maintenance cost.

– Low risk of disease.

– Prevents the loss of dissolved oxygen.

– Improves the work environment.

– Increases the turnaround time for the crops.

– Helps in soil erosion control.

– Low maintenance cost.

– Low risk of disease.

– Prevents the loss of dissolved oxygen.

– Improves the work environment.

– Increases the turnaround time for the crops.

1) High-Density Polyethylene or HDPE Geomembrane

2) Polyvinyl Chloride Or PVC Geomembrane

3) String Reinforced Polyethylene or TSRP Geomembrane

4) Linear Low-Density Polyethylene or LLDPE Geomembrane

5) Reinforced Polypropylene or RRP Geomembrane

6) Ethylene Propylene Diene Monomer or EPDM Geomembrane

2) Polyvinyl Chloride Or PVC Geomembrane

3) String Reinforced Polyethylene or TSRP Geomembrane

4) Linear Low-Density Polyethylene or LLDPE Geomembrane

5) Reinforced Polypropylene or RRP Geomembrane

6) Ethylene Propylene Diene Monomer or EPDM Geomembrane